Standard Operating & Maintenance Procedures

-

Client Challenge

Missing or difficult to use O&M manuals, challenges onboarding and training new staff, loss of institutional knowledge with staffing changes and retirements, inconsistent practices between operators, premature equipment failures, frequent alarms and plant challenges, compliance risks, reactive vs proactive operations and maintenance.

-

How We Can Help

Aureus develops clear, site-specific SOPs that are easy to understand and use - available in written, mobile, and video formats. Created collaboratively with staff, our SOPs include step-by-step instructions for proper operation and maintenance, and include safety, troubleshooting, record keeping and reporting to help improve consistency and quality.

-

Our Expertise

Daily Tours of Duty, Sampling and Testing, Equipment Maintenance, Troubleshooting, Alarm Response, Health and Safety, Calibrations, Chemical Handling, Checklists, etc.

Featured Project

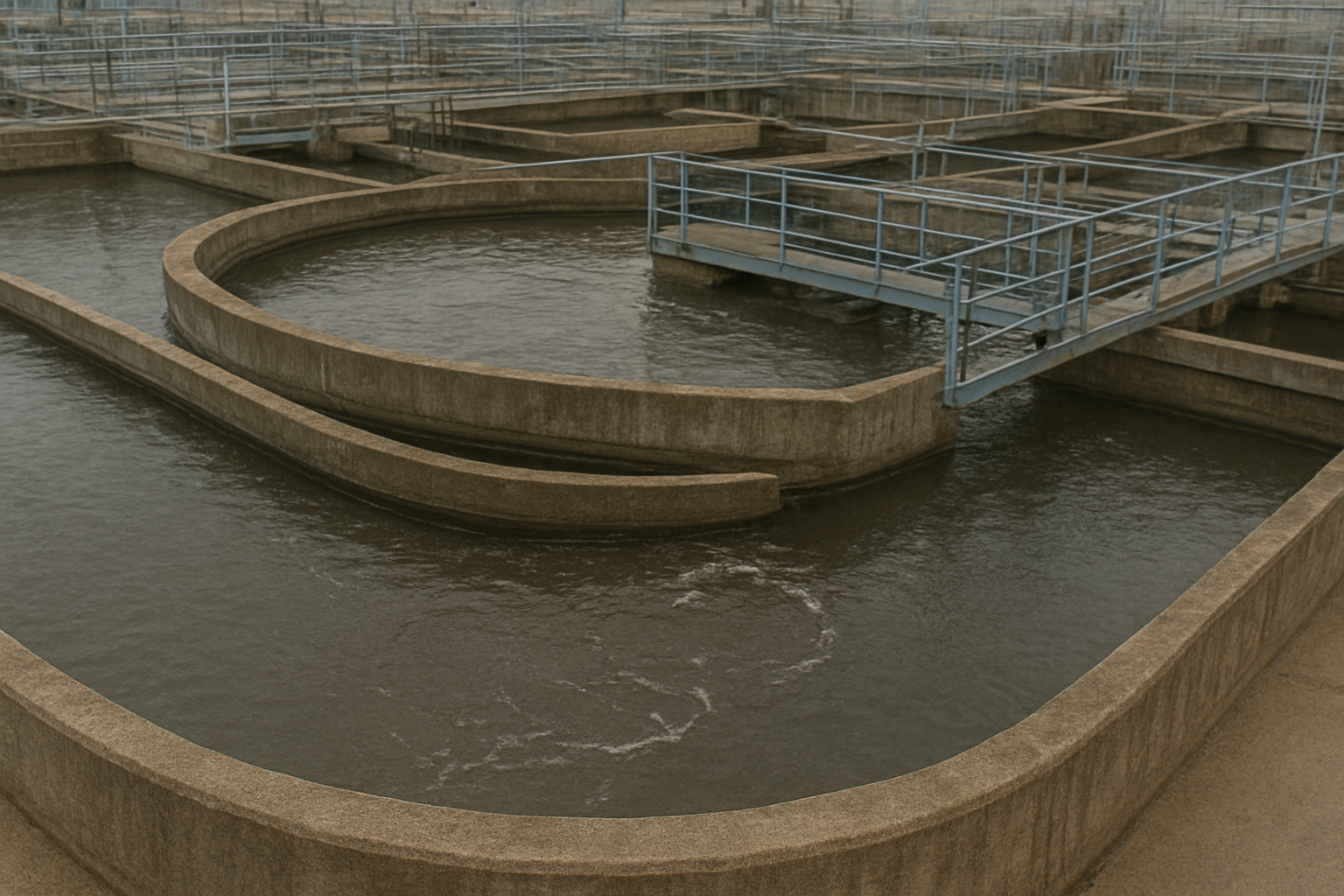

A large food processing facility in Ontario approached Aureus to help standardize its wastewater treatment plant operations following a series of non-compliance events and frequent staff turnover. The site lacked clear procedures for daily monitoring, equipment maintenance, sampling, troubleshooting and emergency response - leading to inconsistent practices, missed compliance requirements, and production challenges. Aureus conducted a site visit to walk through existing operations with staff, then developed a suite of customized SOPs covering tours of duty, sampling and analysis, chemical handling, equipment maintenance, and alarm response. Each SOP was written in plain language with plant-specific terminology, supported by photos of on-site equipment, and formatted for use on mobile devices and as printable guides. Since implementation, the facility has seen improved regulatory compliance, faster onboarding, and fewer operational disruptions.

-

The main objective was to standardize wastewater treatment plant operations to improve compliance, consistency, and reliability at a large food processing facility.

-

The facility experienced non-compliance events and frequent staff turnover. It lacked clear procedures for daily monitoring, maintenance, sampling, troubleshooting, and emergency response, leading to inconsistent practices and production challenges.

-

Aureus conducted a site visit to review existing operations and developed a suite of customized SOPs covering tours of duty, sampling, chemical handling, equipment maintenance, and alarm response. The SOPs were written in plain language, used plant-specific terminology, included photos of on-site equipment, and were formatted for both mobile and print use.

-

The SOPs improved regulatory compliance, supported faster onboarding, and reduced operational disruptions, giving staff a consistent and accessible framework to follow.

-

By embedding standardized procedures into daily operations, the facility strengthened its regulatory performance, enhanced knowledge retention, and reduced its reliance on individual staff expertise.

Contact Us

Interested in working together? Fill out some info and we will be in touch shortly. We can’t wait to hear from you!